Our company has just developed a new feature called SRP Smart Regulated Pressure, which affects spray quality at the nozzle. This option can be integrated into our Xenius display unit, as well as its counterpart for the vineyards, the Xenius Viti.

The SRP option uses the principle of PWM (Pulse Width Modulation).

This project, which has now been completed and is available for sale, enables optimum pressure to be maintained on any spraying system equipped with flow regulation. Working at optimum pressure is important for a number of reasons: it allows spraying with the right size and number of drops in relation to the volume to be spread and the speed of the machine.

The SRP system allows the user to choose the right drop size for the job, which is a sine qua non for quality spraying.

The choice of drop size corresponds to a given pressure, which the SRP system will endeavour to regulate. The major advantage of the SRP system is that it can maintain this pressure at the nozzle despite variations in forward speed, the dose to be applied [L/ha], the number of open nozzles or the number of open sections, which normally cause it to vary.

Working at a regulated pressure at the nozzle ensures a homogenous spectrum of droplets. The spray angle (or spray cone) is complete when the pressure is at its optimum level. When the pressure is too high, the spray angle is too wide, which creates too much coverage of the plot and tends to cause drift.

On the other hand, if the pressure is lowered, spraying is less prone to drift (because the drops are larger/heavier and do not form a volatile mist), but there is a risk of an incomplete spray cone (and therefore areas to be treated are not).

The SRP option allows you to work with an approved nozzle with a wide flow rate range. Thanks to the PWM, you can work with a single nozzle at low or high flow rates over a recommended range. This eliminates the need for manual manipulation of the nozzles on the boom, compared to a system without PWM.

Intelligent pressure regulation also reduces the risk of nozzle clogging and generates larger drop sizes while reducing the dose. In fact, better quality spraying reduces the amount of spray liquid to be applied per hectare. This control allows you to work over a wider range of temperatures and with less favourable hygrometric and anemometric conditions, thanks to the size of the drops.

For a more technical approach, PWM is defined as a type of electrical signal. It is a square-wave signal whose duty cycle and frequency can be varied. Thanks to this PWM principle, the nozzle does not spray continuously but in sequence. Its opening and closing frequency is automatically calculated according to the user’s requirements.

The duty cycle is set automatically according to the choice of nozzle and droplet size via the in-cab terminal: the Xenius or Xenius Viti box.

Our partner has already been able to check the spraying quality of the SRP system in real-life conditions, using water-sensitive paper.

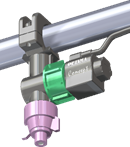

< The OPTIMA electric nozzle, designed specifically for use in agriculture and viticulture.

Result of the droplet spectrum on hydro-sensitive paper following PWM spraying on viticulture. >

What’s more, if your sprayer is not equipped with an OPTIMA system, the company is always ready to listen to its customers’ needs and discuss any nozzle design project that can be adapted to another system*.

If you wish to benefit from the SRP option, you will ideally need to be equipped with a Xenius (Agriculture), Xenius Viti (Viticulture) or ISOBus system. You will also need a pressure sensor and a flowmeter to measure the flow of liquids spread.

If you have any questions or would like more information, you can use the contact form on our website. Our staff can also be contacted on 03.91.801.706 for further information.

*Subject to manufacturer’s agreement.

Pingback: ordering androxal generic how effective

Pingback: buy cheap enclomiphene australia discount

Pingback: how to order rifaximin new zealand buy online

Pingback: buying xifaxan usa buying

Pingback: cheap staxyn generic in usa

Pingback: can i get the avodart pill in chicago

Pingback: how to order dutasteride purchase in australia

Pingback: how to buy flexeril cyclobenzaprine cheap new zealand

Pingback: cheapest buy gabapentin generic does it work

Pingback: ordering fildena us overnight delivery

Pingback: buy cheap itraconazole canada with no prescription

Pingback: srovnání cen kamagra

Pingback: kamagra livraison livraison le samedi